PD4 Series

Equipped with a full range of lighting control functions

Digital control unit PD4 Series designed for ease of use in manufacturing sites

Introducing a new standard model equipped with sequence control and

PLCCOM communication functions that responds to increasingly sophisticated FA environments

AC power cable will be included in the standard model.

AC power cable will not be included in the model with "-NC" at the end.

The product with the model name with "-NC" at the end conforms to the KC standards.

For customers in Korea and Europe, please select model name with "-NC" at the end.

Features

Features

- Continuous lighting, ON/OFF mode, or strobe mode

- Lighting output of 60 W / 120 W available

- Number of channels: 2 channels / 4 channels

- Ethernet / parallel external control

- Trigger input signals and parallel input signals support both NPN and PNP connection

- All types feature natural air cooling, improving installability

Various Lighting Control Functions

- Turn lights on in desired pattern with sequence control function

- Supports PLC link function for easy integration with PLCs

- Trigger output function simplifies the synchronization of the camera and lighting

- With Recipes setting, save lighting settings in a maximum of 8 recipes

- Real-time information monitoring from applications, such as operating status and operation logs

Lineup of PD4/PD4-A Series

We have expanded the PD4 lineup to include the PD4-A Series, which features new lighting control functions.

External control is indicated by the E and P at the end. E: Ethernet P: Parallel

AC power cable will be included in the standard model. AC power cable will not be included in the model with "-NC" at the end.

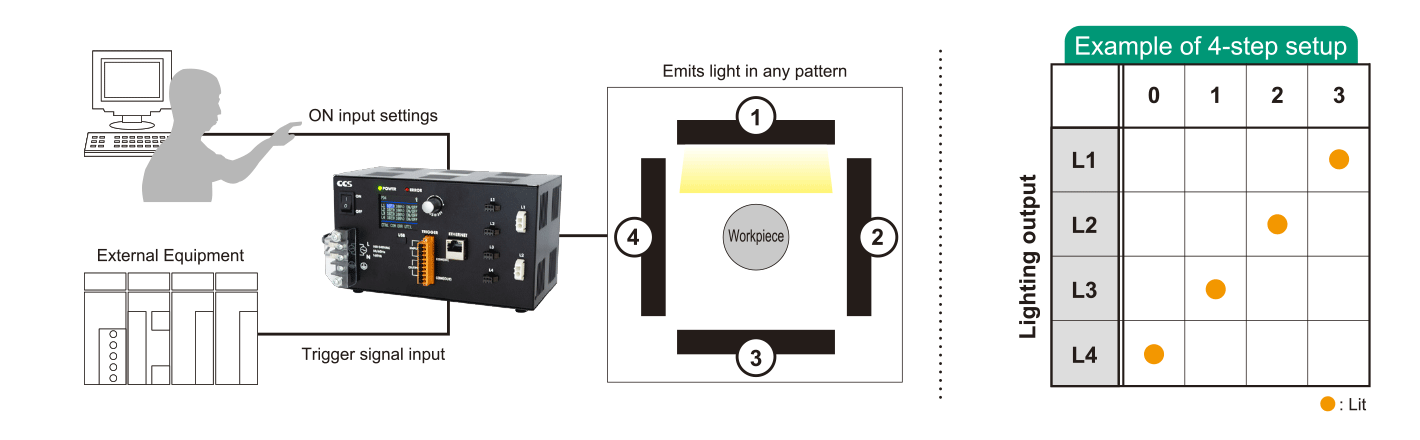

Sequence

Turn lights on in desired pattern with sequence control function

Program up to 16 steps of ON input for a pattern of light emission.

For example, when using 4-quadrant bar lights or segmented lights to illuminate from multiple directions,

the emission patterns for each channel can be stored and switched ON / OFF by trigger input.

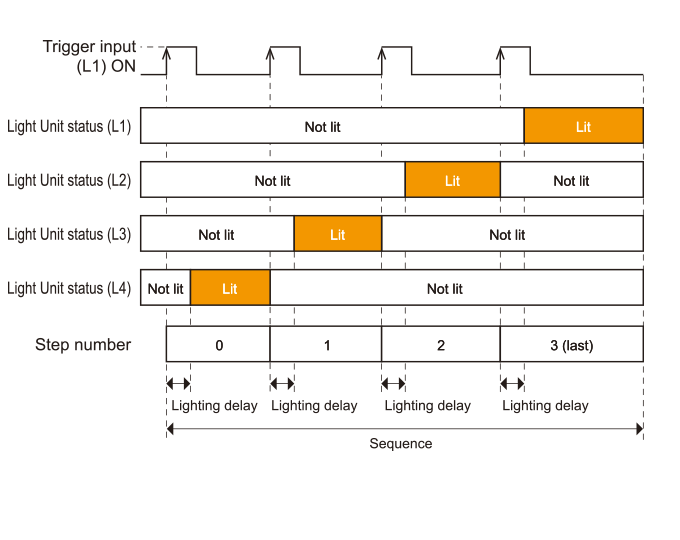

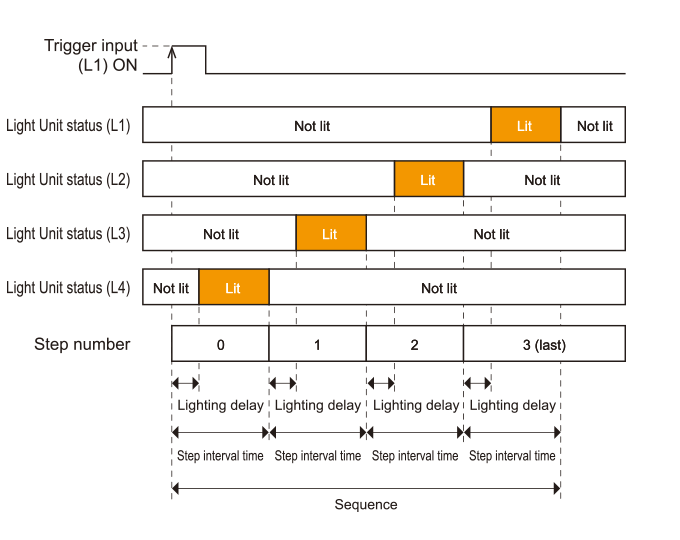

Difference in lighting operation depending on trigger operation mode setting values

Program a maximum of 16 steps of ON input.

Sequence operation can be performed with multiple steps per trigger or 1 step per trigger.

When the Set Value of the Trigger Operation : Mode Is 1-Trigger 1-Step Sequence Operation

When the Set Value of the Trigger Operation : Mode Is 1-Trigger N-Steps Sequence Operation

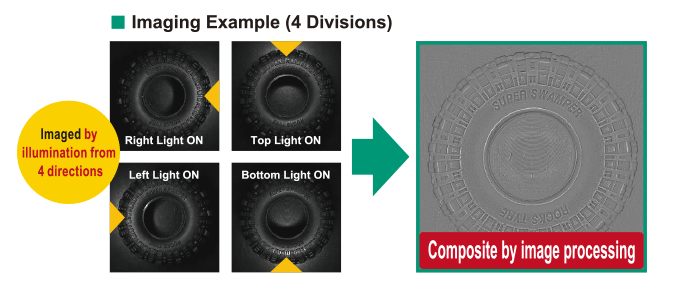

Sequence Control Application Examples

Imaging using photometric stereo method

The workpiece is illuminated and imaged in each direction.

It is possible to generate images that highlight only the unevenness or extract only the pattern by using the differences of each captured image.

For details, see "Sequence Control" on page 10 of the operation manual.

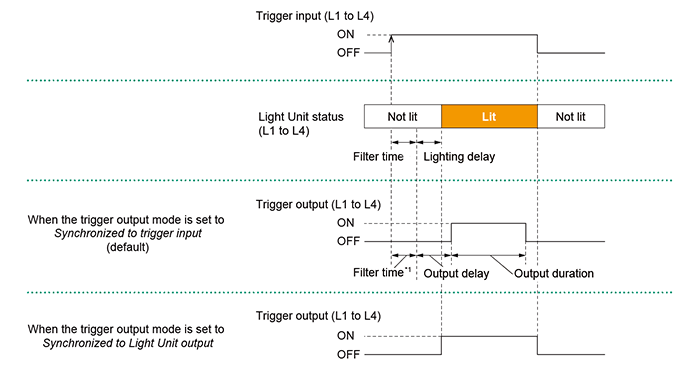

Trigger Output Mode

Trigger signal can be output from the control unit

Sends an output trigger signal to the camera so the timing of the light and camera can be synchronized.

Trigger Output Application Example

*1 Filter time can be set when noise is mixed in with the signal input from the trigger pin.

Recipes

Save lighting settings in a maximum of 8 recipes

Parameter settings such as intensity values for each channel and other inspection-specific parameter settings can be registered in advance, allowing for easy setting changes simply by recalling recipes.

Application

Application (Patent Filed)

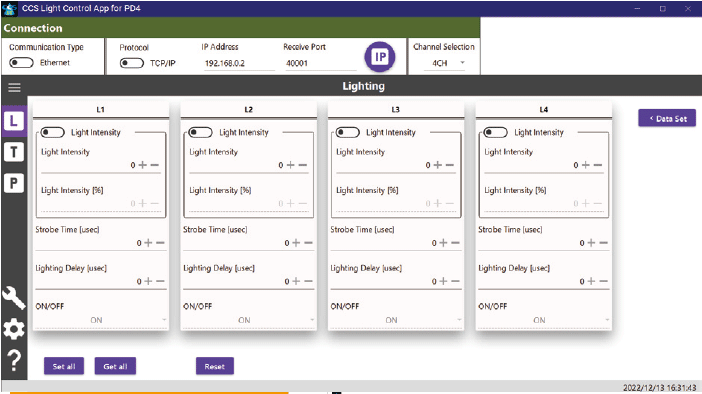

Easy to configure lighting parameters

Two versions: basic version and standard version.

Basic Version

Basic lighting settings such as intensity value and light emission time, as well as trigger input / output settings.

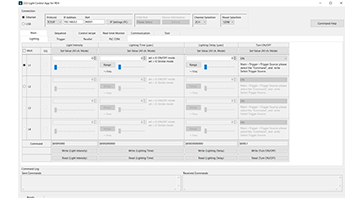

Standard Version

In addition to the functions of the basic version, all functions of the PD4 Series can be configured, including sequence control, real-time monitoring functions, etc.

System Requirements: Windows 10 / NET Framework 4.7.2

* The application can be downloaded from "Product Lineup"

* The standard version application is for the PD4 only

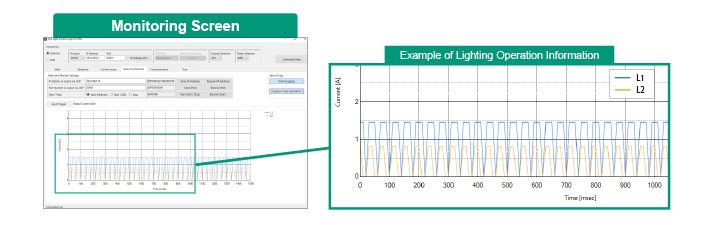

Real-Time Monitoring Function

Real-time monitoring of information such as lighting operation status, operation logs, etc.

Review lighting operation information for verifying lighting status during operation and for cause analysis when a problem occurs.

Communication function

PLCCOM Communication

Supports PLC link function for easy integration with PLCs

PLCCOM communication allows the product to be controlled by reading and writing memory areas on the PLC via Ethernet. Easy to install because there is no need to create a program specifically for the control unit.

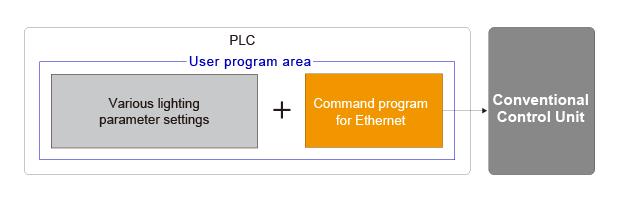

Without PLCCOM Communication [For Conventional Control Units]

A program is needed to communicate with the control unit separately from the various lighting parameter settings.

With PLCCOM Communication [For PD4]

Can be connected via the PLC function, so there is no need to build a communication program.

![With PLCCOM Communication [For PD4]](/shared/images/products/uploads/PD4-A/PD4_communication_02_e.png)

PLCCOM Communication Specifications

| For PLCs supporting MC protocol | For PLCs supporting FINS commands |

|---|---|

| • Device : Data register

• Protocol : MC protocol for MELSEC-Q series • Frame : 3E frame • Transmission code : Binary • Transport : TCP or UDP |

• I/O Memory : DM Area

• Protocol : FINS Commands • Transmission code : Binary • Transport : TCP or UDP • FINS node address : For the TCP setting, specify the address that is automatically assigned by the PLC. For the UDP setting, specify the 4th octet of the IP address of the Control Unit. (Eg. When the IP address is 192.168.0.123, specify 123.) |

For details, see "Overview of PLCCOM Communication" on page 33 of the operation manual.

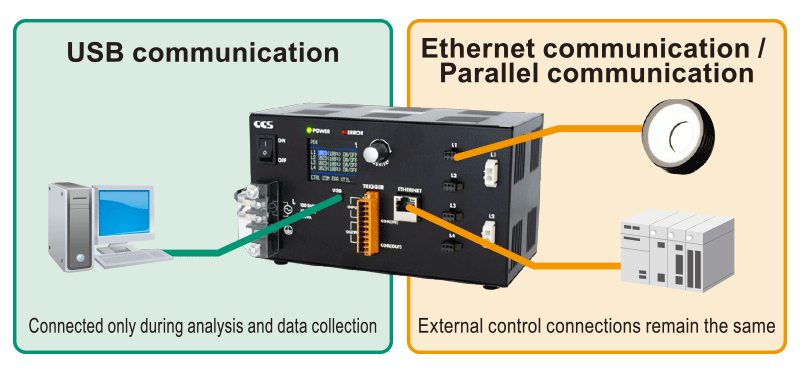

USB Communication

Equipped with a USB connector to enable data communication with a PC while connected to external control devices

Various settings and operations can be verified via USB communication.

Use a USB cable with a ferrite core.

USB Connection Image

Options

Cable

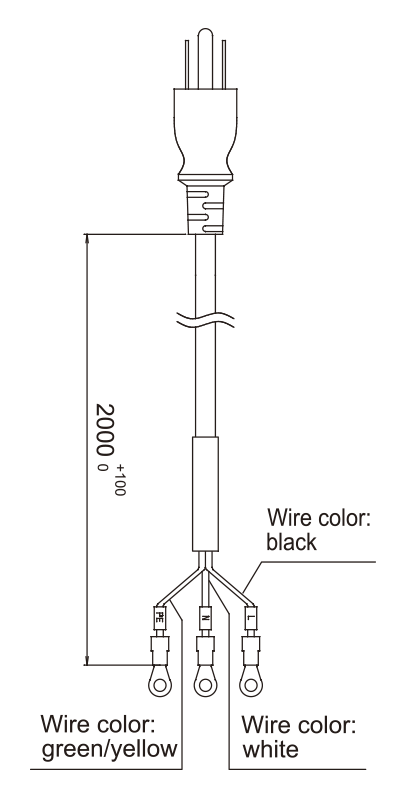

Prong AC Power Cable with Ground Terminal (100-120VAC, 2m)

ACC-JIS-125-7-M4-2

AC power cable will be included in the standard model.

AC power cable will not be included in the model with

"-NC"at the end.

E.g. PD4-6024-4-E (included)

PD4-6024-4-E-NC (not included)

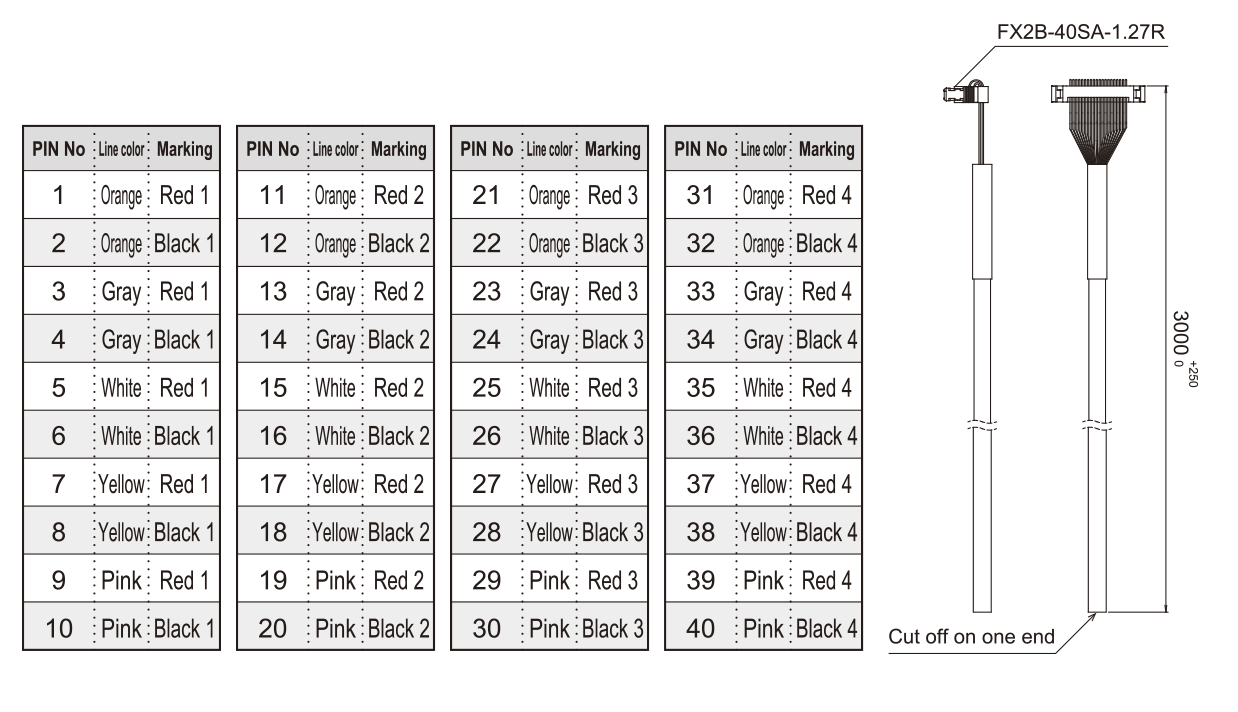

Parallel Communication Cable (Sold Separately)

EXCB2-FX40-3

Parallel communication cable

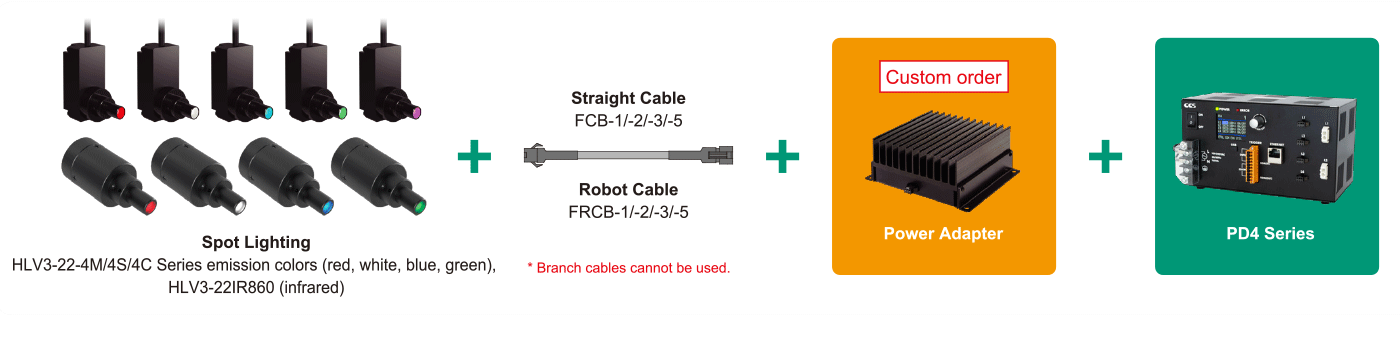

Power Adapter (Sold Separately)

Can be connected to the HLV3 Series by using a control unit adapter

Light and power adapter compatibility table (example)

| Light Model Name | Emitting color | Power adapter model name (Custom order) | ||||

|---|---|---|---|---|---|---|

| HLV3-14 | RD | SW | BL | GR | - | Model name:

RB-82-24-15SP

(Quantity of light: 0.9X, Power consumption: 7.3W *1) |

| HLV3-22-1

HLV3-22-1C |

RD | SW | BL | GR | - | Model name:

RB-56-24

(Quantity of light: 0.8X, Power consumption: 11W *1) |

| HLV3-22-2

HLV3-22-2C |

RD | SW | BL | GR | - | Model name:

RB-56-24

(Quantity of light: 0.8X, Power consumption: 18W *1) |

| HLV3-22-4S

HLV3-22-4M HLV3-22-4C HLV3-22-NR-4 |

RD | SW | BL | GR | - | Model name:

RB-56-24

(Quantity of light: 0.7X, Power consumption: 25W *1) |

| HLV3-22IR860 | - | - | - | - | IR | |

Note) Quantity of light will be lower than when using the PJ Series control unit dedicated for spot lights.

Software Tools

Applicable Software Versions

- 101_100

- 101_101

- 102_100

- 102_101

Upgraded Version: 110_110

Products

-

Machine Vision Applications

Ring

Low-angle Ring

Waterproof Ring

Bar (Area)

Low-angle Square

Flat

Flat Dome

Line Pattern

Dome

Coaxial

Cylinder

High Power Strobe

UV Lights [Ultraviolet Lighting] / Violet Light

IR Lights [Infrared Lighting] (under 1000nm)

IR Lights [Infrared Lighting] (over 1000nm)

Spot

Fiber Heads

Light Source Unit

Line (Convergent Lighting)

Line (Diffused Lighting)

Line (Oblique Angled Lighting)

Reference Light Source

Lights for Fringe Interference Inspection

Custom Order Product

Intensity Control Units [Light Units with Intensity Control Unit ]

OLED(CCS-LT)

Effilux Products

Basler Camera Light Series

- BCL Series (Bar Light)

- BCR Series (Ring Light)

- BCBL Series (Flat Light)

- BCF Series (Flood Light)

- BCL Series (Bar Light) Diffusion Plates

- BCR Series (Ring Light) Diffusion Plates

- BCF Series (Flood Light) Transparent Plate

- BCL Series (Bar Light) Light Polarizing Plates

- BCR Series (Ring Light) Polarizing Plates

- BCF Series (Flood Light) Polarizing Plates

- BCR Series (Ring Light) Light Adapter

- BCL Series (Bar Light) Light Bracket

- Basler Camera Light dedicated cable

-

Control Units

Digital Control Units

Strobe Unit

High Power Strobe Control Unit

PoE Enabled Controller

Controller with EtherNet/IP Interface

LED Light Controller

Control Units [for the HLV Series]

High-capacity Constant-current Control Units

High-capacity Analog Control Unit

Analog Control Units

Control Units [for CCS AItec]

-

Cables

Straight Cables

2-way Cables

4-way Cables

Robot Cables

2-way Robot Cables

4-way Robot Cables

Straight Cables [EL connector type]

2-way Cables [EL connector type]

Extension Cable [for PF Series]

Straight Cables for metal connector (7 pins)

Straight Cables for metal connector (37 pins)

Straight Cables for M12 connector

External Control Cables

Relay Connector

AC Power Cable

-

Options

Filters

Diffusion Plates

- Diffusion Plates [for Ring Lights]

- Diffusion Plates [for LDR-PF Series]

- Diffusion Plates [for LDR-PF-LA Series]

- Diffusion Plates [for Low-angle Ring Lights]

- Diffusion Plates [for Bar Lights]

- Diffusion Plates [for LDL-PF Series]

- Diffusion Plates [for HLDL3 Series]

- Diffusion Plates [for LB Series]

- Diffusion Plates [for Coaxial Lights]

- DF Series

- DF80 Series

Polarizing Plates

- Polarizing Plates [for Ring Lights]

- Polarizing Plates [for LDR-PF Series]

- Polarizing Plates [for Bar Lights]

- Polarizing Plates [for LDL-PF Series]

- Polarizing Plates [for HLDL3 Series]

- Polarizing Plates [for LB Series]

- Polarizing Plates [for Coaxial Lights]

- Polarizing Plates [for IR Series Infrared Lights (over 1000-nm type)]

- PL Series (FASTUS)

Light Control Films

Protective Plates

Adapter [for the CSR Series]

Lens Attachment Rings

Fixtures

Fixtures

Converter

Coaxial Units

Reflection Plate

Condenser lens

-

Lenses

Telecentric Lenses

Macro Lenses

-

Software Tools

Program for controllers

Version Upgrade for controllers

Application note for controllers

-

Agri-Bio Lighting

LED Light Units for Plant Research

ISL-150X150 Series Unit

ISL-150X150 series cables

-

Human Vision Inspection and Microscope Applications

LED Light Units for Microscopes

Request Free Trial

Request Free Trial Request Quotation

Request Quotation Inquiry Form

Inquiry Form Locations

Locations